| Sign In | Join Free | My himfr.com |

|

- Home

-

Products

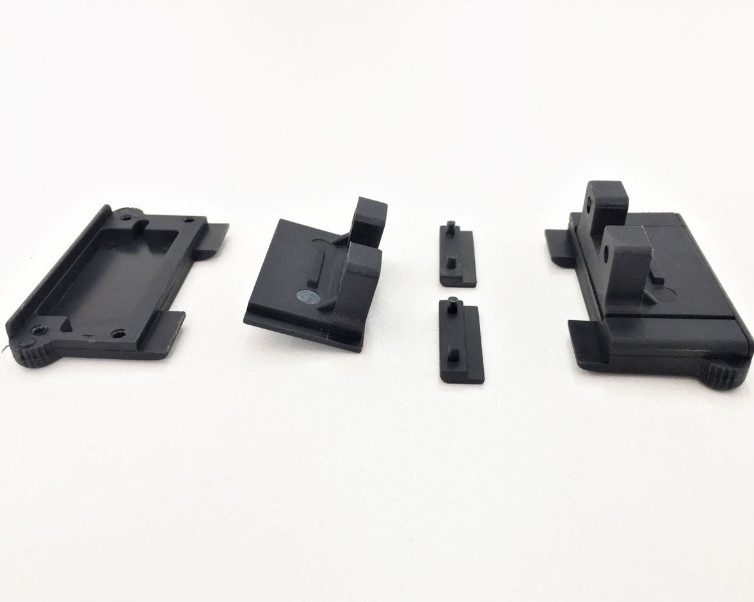

- Injection Molding Molds(74)

- Precision Injection Mould(61)

- Auto Parts Mold(15)

- Plastic Injection Tooling(11)

- Custom Plastic Injection Molding(37)

- Custom CNC Machining(105)

- Custom CNC Milling(96)

- CNC Turning Parts(50)

- Medical Device Plastic Injection Molding(2)

- Plastic Injection Molding Medical Parts(7)

- Plastic Rapid Prototyping(11)

- Bi Injection Molding(12)

- About Us

- Quality Control

- Contact Us

- Get Quotations